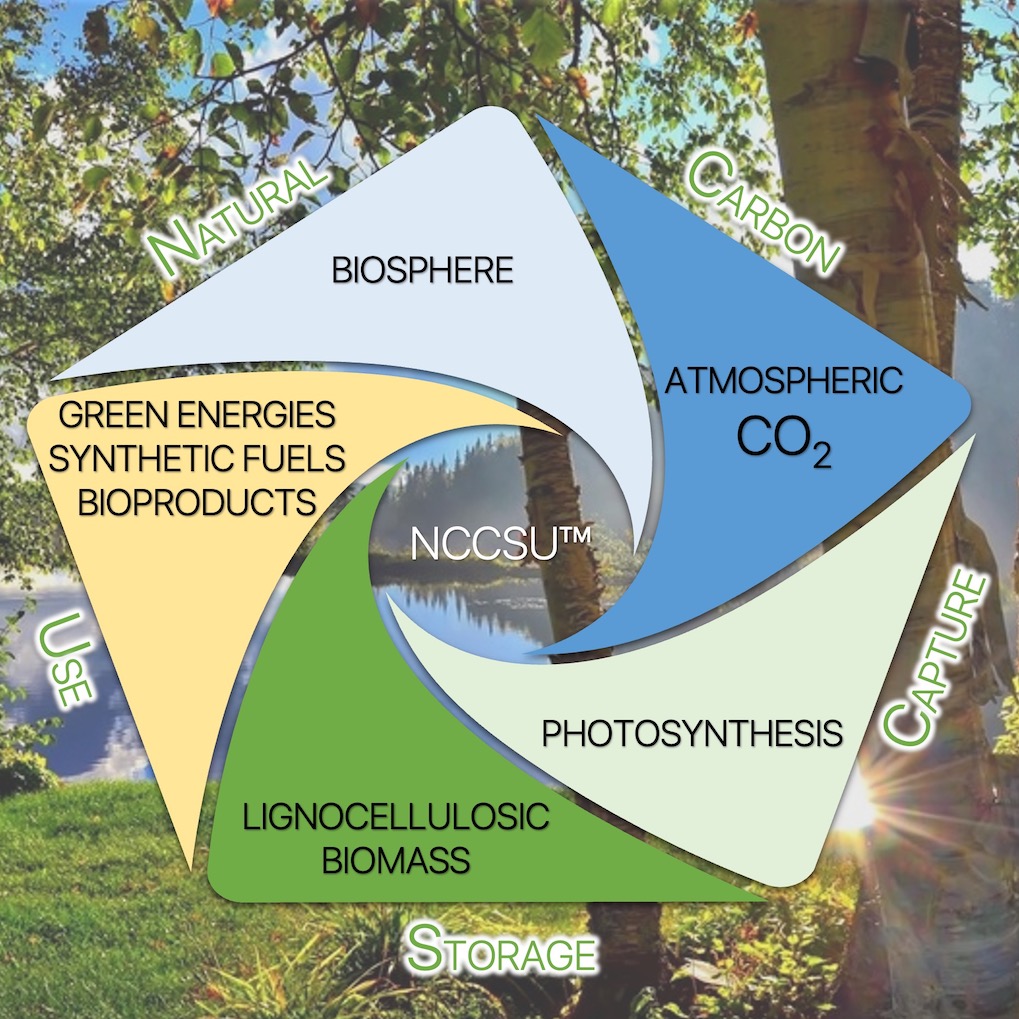

HARNESSING NATURE’S CARBON CAPTURE

Nature already possesses the only effective technology for capturing atmospheric carbon: photosynthesis.

Lignocellulosic biomass (derived from plants and plant residues) captures CO₂ efficiently, ecologically, and renewably.

Abundant and non-food-based, this resource enables the production of sustainable energy and materials, supporting a circular economy.

The underutilized sources of lignocellulosic biomass presented below can be valorized through the LEEBio™ process.

CEREAL STRAWS

Major cereals (wheat, corn, rice, barley, rye, oats, etc.) generate significant volumes of agricultural residues annually.

According to the FAO, global cereal production exceeds 2.8 billion tons per year, a figure that continues to rise. This harvest is accompanied by nearly 2.5 billion tons of straw, which remains largely underutilized.

These non-food resources can be transformed into energy, fuels, and renewable materials through the LEEBio™ process, contributing to a more sustainable and circular economy.

ENERGY CROPS

Energy crops, such as Miscanthus x Giganteus, are a source of lignocellulosic biomass that is simple to produce and harvest.

They require minimal fertilizers and pesticides and can thrive on poor or marginal soils.

Miscanthus, in particular, offers high yields (up to 20 tons per hectare per year) and effectively captures CO₂, making it an ideal carbon resource for producing renewable energy and materials.

THE OIL PALM INDUSTRY

The cultivation of oil palm generates an exceptional amount of lignocellulosic biomass, making it one of the most efficient for CO₂ capture.

Residues such as leaves (OPF), trunks (OPT), fibers (EFB), and shells (PKS) account for over 150 million dry tons per year in Malaysia and Indonesia alone.

Often left to decompose, this biomass constitutes a major renewable resource that can be valorized into energy, biofuels, and bio-based materials through the LEEBio™ process.

THE SUGAR CANE BAGASSE

Global sugarcane production exceeds 1.9 billion tons per year, with 30% becoming bagasse, a lignocellulosic fiber rich in cellulose, hemicellulose, and lignin.

Over 500 million tons of bagasse are generated annually, 60% of which is already used to produce heat and electricity for sugar mills.

The remaining portion remains underexploited, but through the LEEBio™ process, this biomass can be transformed into renewable energy, biofuels, and bio-based materials, supporting a sustainable circular economy.

SUSTAINABLE VALORIZATION OF BIOMASS

All the lignocellulosic residues presented above can ensure global supply of energy and raw materials while respecting the natural carbon cycle through the NCCSU™ concept.

The LEEBio™ process refines these biomasses with unprecedented economic and ecological impact, without the use of fossil energy or resources, paving the way for renewable energy and sustainable bio-based products.