The LEEBio™ process makes it possible to extract high quality products from any kind of lignocellulosic biomass (cereal straw, energy crops, bagasse or palm fibers, wood, etc.)

These products are cellulose pulp, lignin powder, hemicelluloses syrup and silica powder.

These products are homogeneous whatever the origin of the raw material.

The pyrogasification of this cellulose produces a clean renewable syngas.

Existing industrial sites will be able to transform cellulosic syngas into everyday products and fuels.

Lignin, hemicellulose syrup and silica are not degraded compared to other biomass pretreatment processes.

These are bioproducts that can be integrated into industrial sites capable of transforming them without changing their production and distribution methods.

Cellulosic syngas becomes the key to the fossil decarbonization of all existing industries to produce fuels:

Kerosene, Diesel, Methanol, Hydrogen, etc…

using the same equipment and storage and distribution locations.

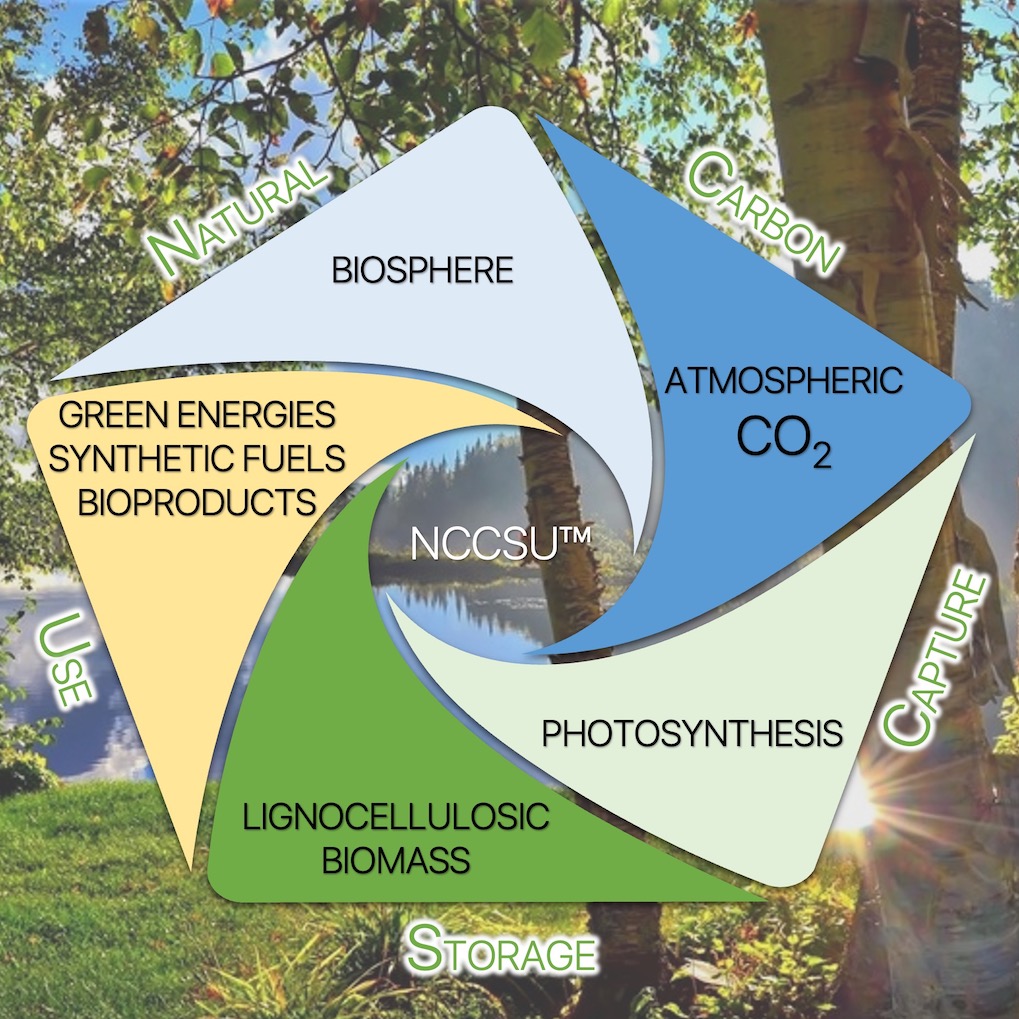

The LEEBio™ process is part of the concept of carbon capture and storage and offers a unique solution for generating sustainable products, fuels and energy from photosynthesis without changing our current habits.

The energy transition must be gradual in order to replace fossil fuels and products with their renewable source equivalents without modifying existing infrastructure.

This is the NCCSU™

The concept of oil refining must be applied to that of biomass refining in order to produce our existing and, above all, sustainable fuels and products.