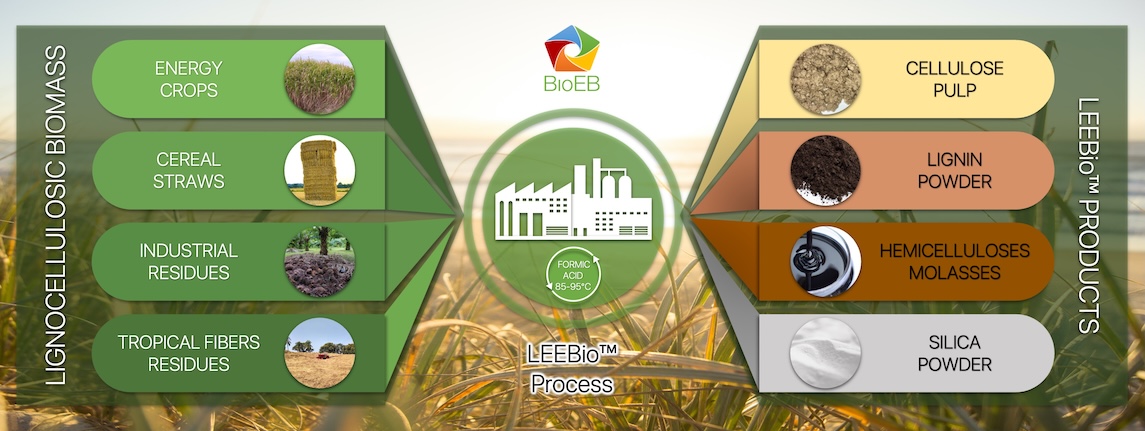

The LEEBio™ process extracts the main constituents of lignocellulosic biomass: cellulose, lignin, hemicelluloses and silica as high-value products

These products are renewable and safe. They can be introduced into industrial sectors without changing the existing technologies infrastructures

CELLULOSE – LEECELL™

It is extracted as an unbleached pulp able to integrate current pulp & paper industries without undesirable effluents.

It is a source of fermentable sugars (glucose) for the production of low-carbon Biofuels.

This cellulose pulp can be converted into a clean and renewable synthesis gas that can be industrially transformed into existing fuels such as Kerosene, Diesel, Methanol & Hydrogen

LIGNIN – LEELIGNIN™

It is a sulfur-free lignin extracted as a brown powder.

It is a phenol and polyol products with a well-established structure.

It can substitue phenol and PEG (PolyEthylene Glycol) in their applications such as phenolic resins, epoxy resins and polyurethanes.

Depending on its origin, this lignin can be an excellent low cost carbon fiber precursor, particularly sought after in automotive industries.

This lignin product is reproducible from the same raw material.

HEMICELLULOSES – LEEXYL™

It is extracted in the form of molasses (or black treacle).

This kind of syrup is rich in oligomeric xylose (up to 70%), proteins and natural elements. Mannose sugar is highly present in softwoods based molasses.

This molasse can be used as a strong nutritional and tanning agent in animal nutrition.

It is also suitable for the production of Furfural, 2,5-furandicarboxylic acid (2,5 FDCA), 2-methylfuran, Xylitol or biofuels based products.

SILICA – LEESIL™

When the lignocellulosic feedstock is rich in silica content (> 1%), specifically in cereal straws and energy crops, it is possible to extract it using existing processes in industry after an alkaline washing of LEECELL™ pulp.

This form of precipitated silica is particularly appreciated in high-tech or medical industries for its reinforcement, adsorption and polishing characteristics, but also in tire industry.