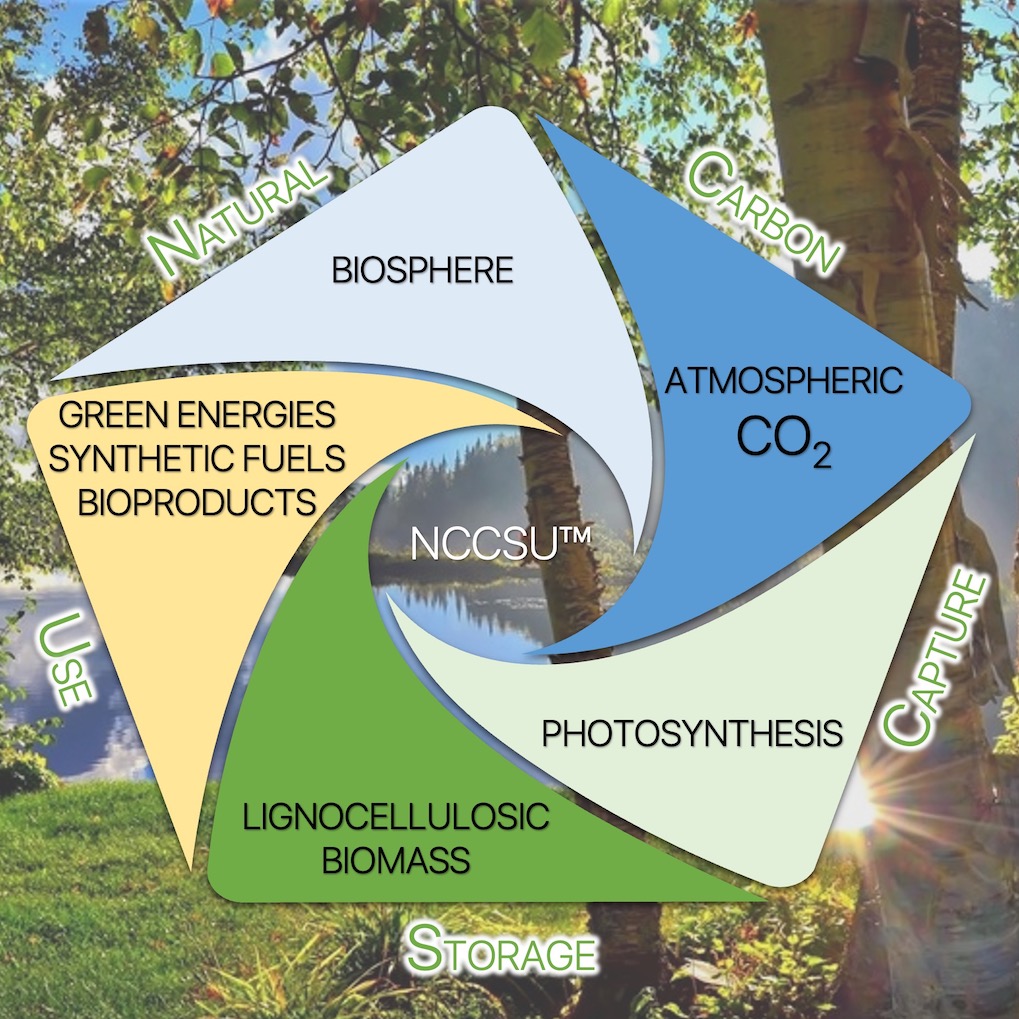

THE CAPTURE OF NATURAL CARBON

Through photosynthesis, lignocellulosic biomass captures atmospheric carbon in the most cost-effective and environmentally friendly way in the form of CO2.

The global supply of lignocellulosic biomass is more than sufficient using only its residues to provide renewable energy and products for our world.

These lignocellulosic biomass residues are shown below and can be separated by the LEEBio™ process.

CEREAL STRAWS

Cereals concern all varieties of wheat, corn, rice, barley, rye, oats, etc.

The FAO (Food and Agriculture Organization) forecasts an annual cereal harvest of around 2.5 billion tonnes per year.

This means that nearly 1 billion tonnes of cereal straw could be made available and valorized for renewable energies and products with the LEEBio™ process.

ENERGY CROPS

It is the easiest type of lignocellulosic biomass to recover and produce.

Energy crops require little fertilizer, few pesticides and they thrive on poor soils or extensive pastures.

Among the widespread energy crops, Miscanthus is considered the most suitable carbon resource to provide energy and products to the world.

THE OIL PALM

Lignocellulosic biomass generated by the production of palm oil industries is by far the most prolific crop in terms of atmospheric CO2 capture on Earth.

With EFB and PKS, the industrial lignocellulosic production of these palm trees consists of dry leaves (Palm Fronds) and trunks (Palm Trunks).

Until today, nearly 300 million dry tons are produced annually to be left on the ground and rot, causing pollution and various associated risks.

THE SUGAR CANE BAGASSE

Nearly 2 billion tonnes of sugar cane are produced annually around the world. About 30% of sugar cane is composed, after extraction, of fibrous material called bagasse.

More than 200 million dry tons are therefore collected each year and used in part to provide the thermal energy necessary for sugar factories.

WOOD RESIDUES

FAO reports global dry wood production of around 4 billion tons per year.

In industrial forestry, 1/3 of the wood remains on site and becomes an undeveloped lignocellulosic residue.

Its advantage is to be available without changing the current operating system of industrial sites.

NCCSU™ and LEEBio™

All of the lignocellulosic residues presented above will ensure the global and necessary supply of energy and raw materials while respecting the natural carbon cycle through the NCCSU™ concept.

The LEEBio™ process extracts these products from these raw materials with an unprecedented economic and ecological impact.

Without the use of fossil resources.